CONTACT US

Laiwu Yida Materials Technology Co., Ltd.

ADDRESS:No. 191 Wudangshan Road, Laiwu High-tech Zone, Shandong Province

Email:lwydxcl@126.com

Web:www.qddongshuo.cn

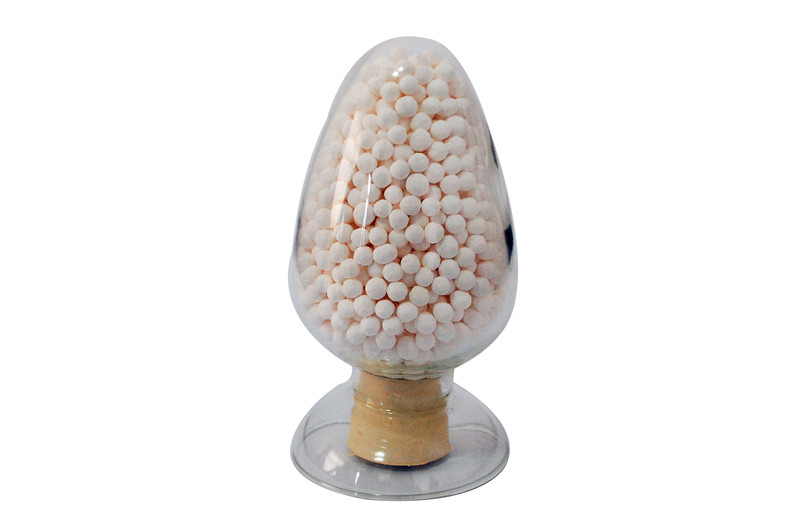

Preparation and Properties of High Temperature Resistant and High Specific Surface Area Activated Alumina

Activated alumina as catalyst carrier is widely used as vehicle exhaust catalyst, petroleum refining catalyst, hydrogenation and hydrodesulfurization catalyst at high temperature at home and abroad. Alumina is an ionic bond compound with strong chemical bonding force. According to its crystal structure, there are many kinds of homogeneous and heterogeneous crystals, such as delta-, _-, kappa-, _-, beta-, gamma-and alpha-Al2O3. Among them, the main and important applications in industry are gamma-Al2O3, beta-Al2O3 and alpha-Al2O3. At present, gamma-Al2O3 is the most widely used coating material with good effect of enlarging surface area. Gamma-Al2O3 is usually obtained by burning the hydrate of alumina (Al2O3.nH2O). However, the gamma-Al2O3, which usually constitutes the active coating, will change into a-Al2O3 at above 800 C, resulting in the increase of density and the decrease of surface area, resulting in the collapse of pore structure. Moreover, the activated coating will fall off the carrier above 1200 C, which will increase the gas resistance and decrease the catalytic activity. The addition of La203 can stabilize the crystal structure of gamma-Al2O3, stabilize the activated coating at high temperature and inhibit the loss of activity. In this paper, the preparation and properties of activated alumina with high temperature resistance and high specific surface area were systematically studied. In the research of heat stabilizer, it was found that the effect of La3 + modification was the best, followed by Ce4 + modification, while that of Pr3 +, Nd3 +, Sm3 + modification was the worst, Er3 +, Y3 + modification was the worst. The order is exactly the same as that of La3+> Ce3+ > Pr3+ > Nd3+ > Sm3+ > Er3+ > Y3+, indicating that the larger the ion radius, the better the stabilization. At the same time, the valence state of ions will also affect its stability, which is mainly due to the large radius and high valence state of ions will reduce the mobility of ions, which can be fixed on the surface of alumina at high temperature to prevent the sintering of alumina. Because La203 is more prominent. At the same time, its price (RMB 30 per kilogram) is relatively low, so its application prospect is better. I have determined that lanthanum oxide is the best heat stabilizer for alumina carrier. Among the preparation methods of active alumina, AlCl3, Al2 (SO4) 3, Al (NO3) 3 sol method and (NH4) Al (SO4) 2, (NH4) Al (CO3) 2 decomposition method were mainly investigatedUnder the same other conditions, namely, the heat stabilizer is La2O3, the pore enlarger is PEG, activated carbon and EDTA, and the prepared alumina particles are calcined at 1200 C for 1 h. Then, the activity of alumina particles is analyzed by DAT and SEM. It is found that AlCl3, Al2 (SO4) 3 and Al (NO3) 3 have large particle size and low specific surface area because of the sol method. As a new type of non-polluting material, (NH4) Al (CO3) 2 has become a hot spot in recent research. In (NH4) Al (CO3) 2 decomposition method, because the decomposition temperature of CO2 is lower than SO42-decomposition temperature, although it can be generated during calcination. Small particles of alumina can not form foamed alumina, so the activity of high temperature alumina formed by (NH4) Al (CO3) 2 decomposition method is slightly higher than that of sol method. And (NH4) Al (SO4) 2 decomposition method has formed a foamed alumina structure during high temperature treatment. Compared with other preparation methods, (NH4) Al (SO4) 2 decomposition method, the highest temperature alumina particles are the smallest, the activity is the highest and the specific surface area is the largest, so it is determined. Ammonium aluminium sulfate is the best reagent for preparing high temperature resistant and high specific surface area activated alumina. In the preparation of low temperature activated alumina, additives such as phosphate and silicate can effectively improve the activity of alumina. Therefore, in the process of preparing active alumina with high temperature resistance and high specific surface area, additives phosphate and silicate were added to analyze the activity of alumina particles by DAT and SEM. The experimental results show that although the specific surface area of alumina is increased by adding additives such as phosphate and silicate, the increase is very small, and the specific surface area of activated alumina is not reached. Therefore, the method of using additives is not suitable for the preparation of high temperature resistant active alumina. Commonly used pore enlargers such as (NH4) 2CO3,PEG, activated carbon and EDTA can effectively improve the activity of activated alumina, but they have little effect in the preparation of high temperature resistant and high specific surface area activated alumina. The main reason is that the decomposition temperature of pore expander is too low. In this experiment, solid containing [La(EDTA)] was synthesized as pore expander. Through the experiments of pore-expanding ammonium aluminium sulfate, DAT and SEM analysis, the following conclusions were drawn: high-temperature pore expander containing [La(EDTA)] solid was synthesized. By mixing solid with solid, the macroporous structure of all the experimental samples increased, resulting in their larger specific surface area at 1200 (?) C. Scanning electron microscopy (SEM) shows that alumina is a porous network with a large pore size of 10-30um at high temperature. The specific surface area of the four samples calcined at 1200 ([La(EDTA)]-= l% for 1 h is more than 120 m2/g. The specific surface area of the samples with x([La(EDTA)]-= l% is 150.36 m2/g, which is much higher than that of the same literature. Activated alumina with high temperature resistance and high specific surface area was prepared by pyrolysis of ammonium aluminium sulfate. The thermal stabilizer is La2o3, the molar fraction of La2O3 and A1203 is 1:100, and the pore expander is the compound H[La(EDTA)] 6H_2O crystal synthesized by EDTA and thermal stabilizer, its molar fraction with thermal stabilizer is 1:1.